Powerful brakes ensure reliability – our centrifugal for your safety!

Centrifugal brakes

How does a centrifugal brake work

Do you need a centrifugal brake to secure your users and applications? Then you have come to the right place. Here you will find an overview of the function and advantages of Amsbeck centrifugal brakes:

The centrifugal brake works in principle like a centrifugal clutch. In the clutch, the housing is not fixed and starts to rotate when the engagement speed of the clutch is reached and transmits torque as the speed increases. With the centrifugal brake, the housing is fixed and secured against rotation.

Good to know: A centrifugal brake does not brake to a stop. The main application for centrifugal brakes is to limit speed to a safe level.

Functional principle of centrifugal brakes

Guided weight elements set in rotation experience a radial force component which accelerates them outward. This force is compensated by spring forces up to the defined engagement speed.

When the switch-on speed is reached, the friction linings are in contact with the housing and the torque build-up on the housing begins. Increasing the speed leads to quadratically increasing forces and thus to increasing torques. The brake is at the beginning of the operating range. The working range is between switch-on and the torque equilibrium between load torque and braking torque. This torque equilibrium must lie in the slip range of the brake.

As long as the centrifugal brake is not switched on, so the spring force outweighs the centrifugal force, the system operates without contact and without losses. In order not to affect the brake function, fat, oil and wetness must be kept away from the friction surfaces.

By varying the springs, the friction material, the size, the number of parallel elements and the operating speed, the engagement speed and torque are determined and adapted to the specific application.

Engaging the centrifugal brake

Basically, the switch-on speed is determined by the balance of load torque and braking torque. Since the power of a centrifugal brake increases quadratically with increasing speed, a minimum operating speed of the braking system is required. The cut-in speed of a centrifugal brake describes the speed at which the mass of the centrifugal weights, due to the centrifugal forces acting on them, overcomes the restraining force of the springs. By selecting springs of different strengths, which retain the centrifugal weights for different lengths of time, the engagement speed can be varied. Because of these interrelationships, a centrifugal brake cannot brake a system to a standstill; they often serve as speed limiters.

Dimensioning

Centrifugal brakes are generally safety-relevant components, so careful design and consideration of the operating conditions is essential. For the correct design of the centrifugal brake, the following parameters are therefore important in addition to the respective application:

- Operating speed

- Engagement speed

- Frequency of braking operations

- Braking time

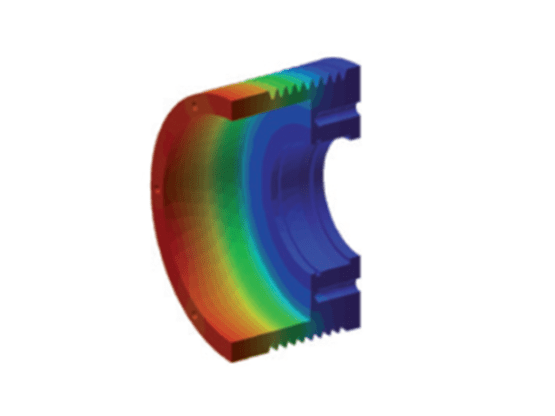

Heating of the centrifugal brake

Friction generates heat, so a centrifugal brake converts the friction work performed completely into heat. The heat is generated directly in the frictional contact and essentially heats the material that is directly involved in the frictional contact (see Fig.). The heat generation depends on the respective operating conditions as well as on the following factors:

- Braking torque

- Size of the clean area

- Braking time

Heat conduction causes heat to be distributed throughout the entire brake. The temperature rises sharply at the start of braking and levels off as it progresses until a maximum is reached. When designing a brake, care must be taken to ensure that the maximum permissible temperatures in the friction contact are not exceeded, as otherwise significantly increased wear will occur on the friction lining. This thermal overload significantly changes the friction values and can have a negative effect on the function of the brake. Due to the resulting surface temperatures, protective devices may be necessary in the area of the brake.

Structure of the centrifugal brake

Each centrifugal brake consists of a profiled hub on which centrifugal weights are held together by lining hanger with brake linings (friction material) by tension springs. The inner workings of the brake are pressed into the brake housing with bearings and secured by cover discs and circlips.

Fields of application at a glance:

Speed limitation when lowering people or weight from heights to the ground:

- Gate systems / fire protection curtains

- Free time applications such as ziplines

In which applications is the centrifugal brake used?

The main area of application is in speed limitation. Often there are centrifugal brakes in descenders, which gently lower people to the ground in case of danger. Safety engineering is a broad field of centrifugal brakes.

In addition to descenders, centrifugal brakes are used in cranes, elevators, gate systems and fire curtains. But people are also secured in leisure applications such as ropeways, which you are certainly familiar with or have also used.

What advantages do you gain when using Amsbeck centrifugal brakes?

- As a safety brake, the centrifugal brake provides an additional safety feature for your users and applications. Ideally suited for braking systems.

- It is often used as a backup braking system to the electronic brake.

- The centrifugal brake operates purely mechanically and has the advantage that it reliably and safely brakes the speed until a permissible lowering speed is reached, regardless of any other energy supply.

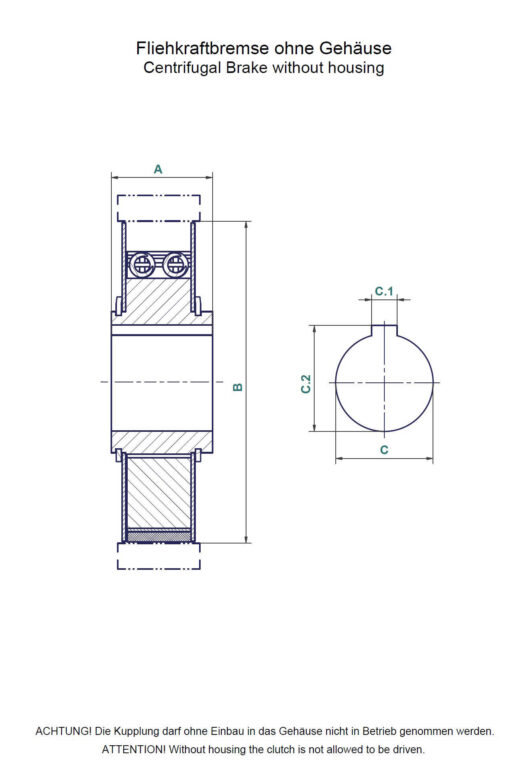

- If a brake housing is available on your part, we deliver the centrifugal brake without housing.

- Simple and cost-effective replacement of wear parts such as brake pads and tension springs

- Individually adapted to your application and requirements. Examples can be found in the overview below.

- Experience and KnowHow for more than 40 years

Would you like to check whether the principle of the centrifugal brake is suitable for your application? Feel free to contact us by phone, contact form or e-mail. Our team will be happy to coordinate the technical design with you.

An overview of our

Centrifugal brake

Centrifugal brake

Centrifugal brake

Centrifugal brake

Do you have any questions? Please contact us.

Product enquiry form

Centrifugal brake without housing

© copyright 2025 | Amsbeck