How does a centrifugal clutch work?

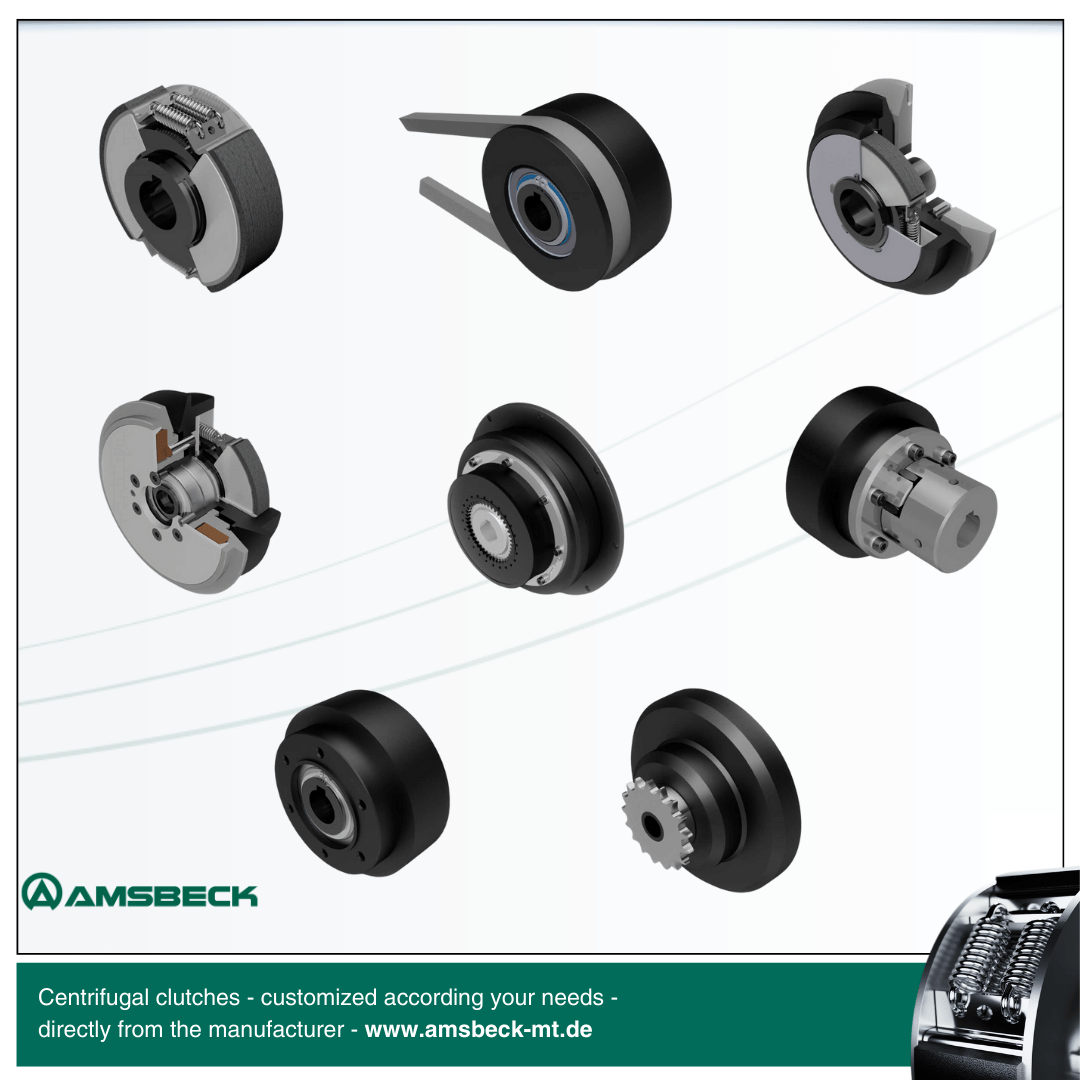

Centrifugal Clutches: Efficient Power Transmission for Maximum Performance

Centrifugal clutches play a crucial role in various applications – from construction machinery and kart engines to industrial equipment. But how do centrifugal clutches work, and why is choosing the right clutch so important?

How a Centrifugal Clutch Works

Centrifugal clutches operate using the principle of centrifugal force.

As the engine speed increases, the clutch components move outward, engaging with the clutch drum. This enables efficient power transmission – at lower speeds, the clutch remains disengaged, allowing smooth idle control.

Advantages of Our Amsbeck Centrifugal Clutches

Our clutches are designed to meet the highest demands, offering:

- Precise Engagement Speed:: Adjustable tension sprinsg allow fine-tuning for optimal performance.

- High Torque CapacityDurable materials ensure maximum power transfer.

- LongevityAll wear parts are replaceable, significantly extending the clutch’s lifespan.

- Reliability: Every clutch is tested before shipment to guarantee consistent performance.

Key Factors in Choosing the Right Centrifugal Clutch

When selecting the perfect clutch, consider the following factors:

- Engine Power:The clutch must match the engine's power output to prevent excessive wear or slipping.

- Engagement speed: Proper calibration ensures smooth power transmission and prevents power loss.

- Maintenance & RepairSpare parts and repair kits make it easy to keep the clutch in top condition.

Conclusion

Centrifugal clutches are a key component for efficient power transmission. With our extensive experience and high-quality manufacturing, we ensure that our customers always receive the best solution for their application.

🔗 Contact us today – let’s find the perfect centrifugal clutch for your needs!

© copyright 2025 | Amsbeck