UNI Göttingen

Reach your destination with safety!

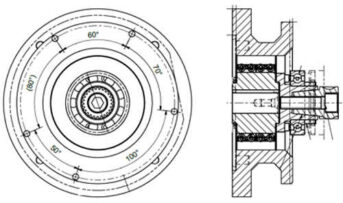

Centrifugal brakes ensure safety in the goods transport system at UNI Göttingen.

The goods transport system of the University of Göttingen supplies the entire hospital with everything that is needed, from food to medicines - within the shortest possible time.

. Unfortunately, this was not always the case in the past. The system installed in the mid-1970s repeatedly caused wagons to crash in the vertical sections. The damage to the material and the delays in transport were sometimes considerable - a solution had to be found. So Amsbeck received an initial inquiry about the feasibility.

"We are looking for a suitable braking system for fall protection of an automatic driving system..."

After a thorough review of the task and intensive discussions with the customer, a solution approach was developed. The difficulty was that there were no CAD drawings due to the age of the plant. However, the brake had to be attached to the existing construction. Therefore, Amsbeck was provided with a wagon including motor and gearbox to enable an exact adaptation of the brake unit to the construction of the transport wagon.

After a detailed analysis of the actual situation, a proposal for a prototype was developed and presented to the responsible persons at the University of Göttingen.

The prototype of the centrifugal brake was commissioned and subjected to intensive stress tests. It quickly became apparent that the brake could safely prevent an uncontrolled crash of the wagons, even under the most difficult conditions - the acid test was passed.

"The brakes have already paid off..."

"The first brakes, which have now been in service for a good 12 months, have already been able to prove their function a few times. Since installation, there have been no more uncontrolled crashes."

Says project manager Daniel Hartje.

The reliability of the goods transport system could be restored and the important transports reach their respective destinations safely again.

04.07.2019, Everswinkel

© copyright 2022 | Amsbeck